Commissioned koji Production

Advantages of Koji Processing

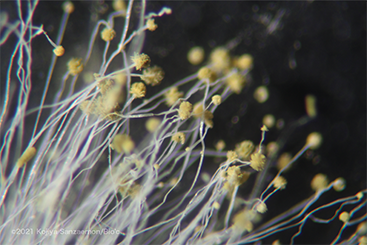

Koji is said to be a "treasure house of enzymes," as it produces a wide variety of enzymes during the growth process of koji mold.

The function of these enzymes, for instance, maximizes the potential of the material and adds value and new functions and features to it.

Development of Koji materials

We, Bio’c can develop koji by processing your materials, not to mention rice, soybeans, wheat, and other grains that have traditionally used as koji.

Today, various value standards are being created, koji processing can be used to create high value-added products or The reuse of materials.

Koji processing that can only be done by bioc

Based on our knowledge of koji production inherited from Kojiya Sanzaemon, which was founded in the Muromachi period, and our experience in dealing with more than 3,000 companies worldwide, we provide full support from inquiry to development.

Bio’c has about 3,000 varieties of koji molds with different properties and characteristics. We can compare them according to the material and purpose, and produce koji with the most suitable koji.

By using large-sized special koji cultivation equipment, we can prevent miscellaneous bacteria from mixing in and produce a large amount of safe, high-quality koji that is purely cultivated from the desired koji at one time.

Examples of changes due to Koji processing

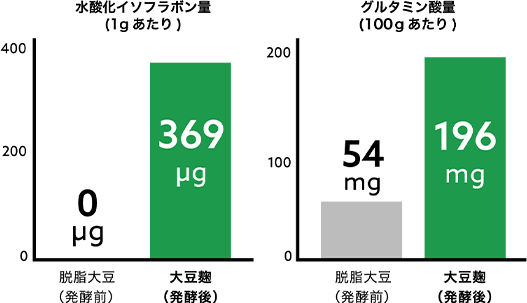

In "Soybeans Koji," a material jointly developed with Toyo Hakko, "hydroxylated isoflavone," which has strong antioxidant and anti-glycation functions, is produced through koji processing. Hydroxylated isoflavone is an ingredient that is not contained in soybeans themselves, but is produced by koji-forming soybeans. In addition, the protein contained in soybeans is broken down to free amino acids, so its absorption by the body is dramatically increased compared to soybeans, and glutamic acid, which is involved in flavor, is also overwhelmingly increased compared to before fermentation.

Koji processing of coffee beans has shown that there are combinations of koji and coffee beans that show changes in both appearance and flavor compared to before fermentation. This example will add characteristics to products that would otherwise be low grade or discarded, and is expected to lead to reutilization of materials and higher value-added products.

Coffee bean Koji is an initiative with Sho Aoyama, a taste planner.

By processing quinoa with black koji mold, a unique, pitch-black appearance and unique flavor was created. This appearance was described as "caviar of the forest" at an event to unveil a cafe menu using quinoa koji, and succeeded in giving the dish a unique character.

Quinoa Koji is an initiative with Yuta Suzuki, a food creator.

Flow chart for completion of koji-processed materials

Online support is also available.

We can propose and select the most suitable koji mold for your purpose and materials.

Up to 10 kg of raw material

to the designated factory, etc.

50-300 kg of raw material/test

We verify the quality of test products through inspections, etc.

Please feel free to contact us for more information.

here to contact.